When a multi story or single story steel building is being designed there are many components that you have to consider. From the frame, walls, roof, floor and so on, the engineer has many factors that need to be accounted for.

One major component is the metal decking floor system. There are many ways to design and construct a stronger metal decking floor system. However, not all design options are best.

Most of your options to make the floor system stronger require adding extra weight, which has an impact on other aspects of the building such as the steel framing.

Composite metal floor deck systems are designed to be a solution to this specific problem. The main benefit of a composite metal floor deck is strengthening your floor system without adding extra weight.

Composite metal floor deck comes in different profile types, gauges and lengths. Each profile type and gauge is engineered for different concrete slabs and yields different values in strength. Not all projects are engineered the same. Some areas may require more strength and that requires a heavier gauge or different profile type. Western Metal Deck stocks a large assortment of composite metal floor deck in different profiles, types, and gauges.

In this article we will cover:

- What is Composite Metal Floor Decking?

- Types of Composite Metal Floor Deck

- Alternatives to Composite Metal Floor Decking

- Benefits of Composite Metal Floor Deck

What is Composite Floor Decking?

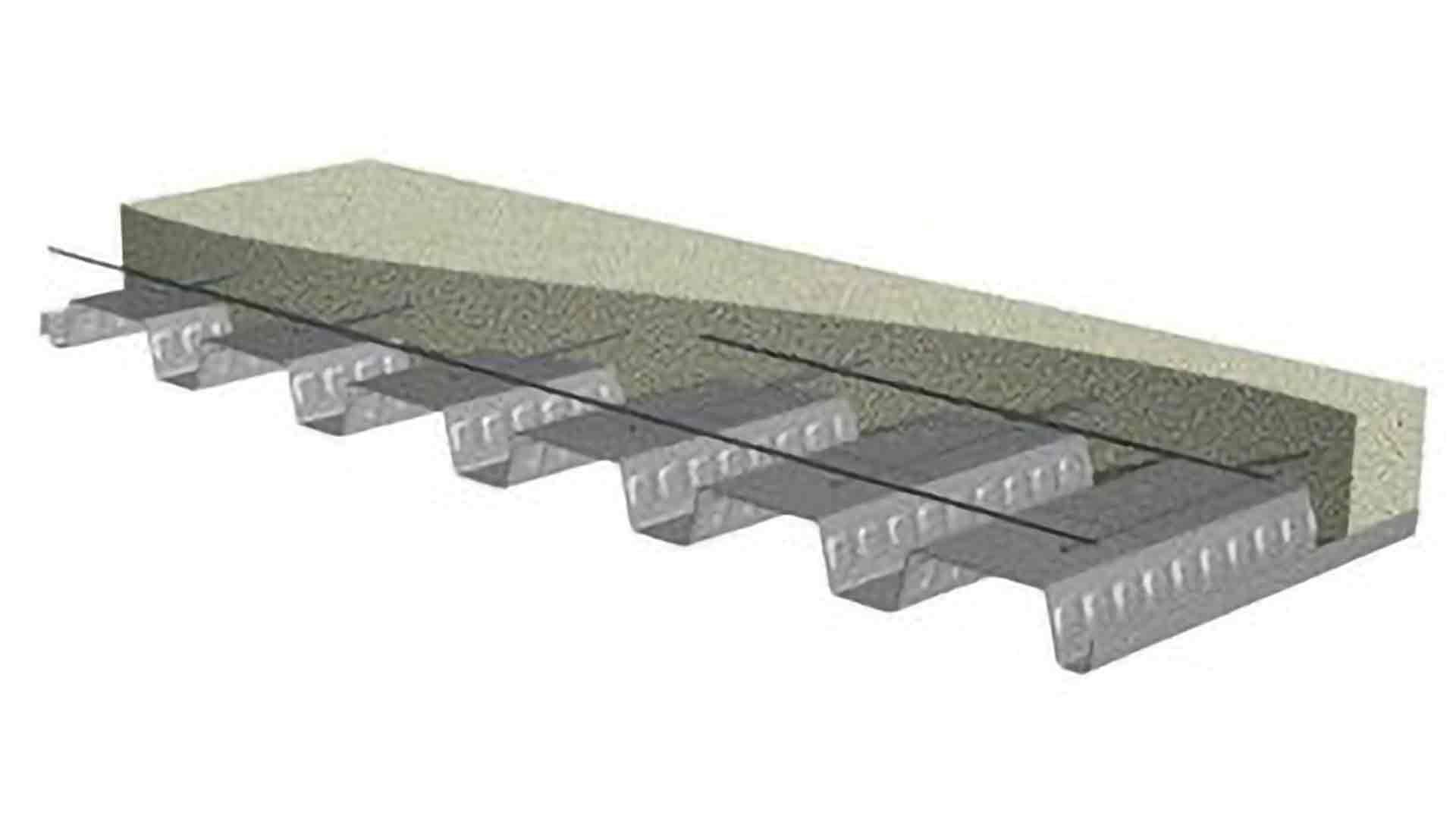

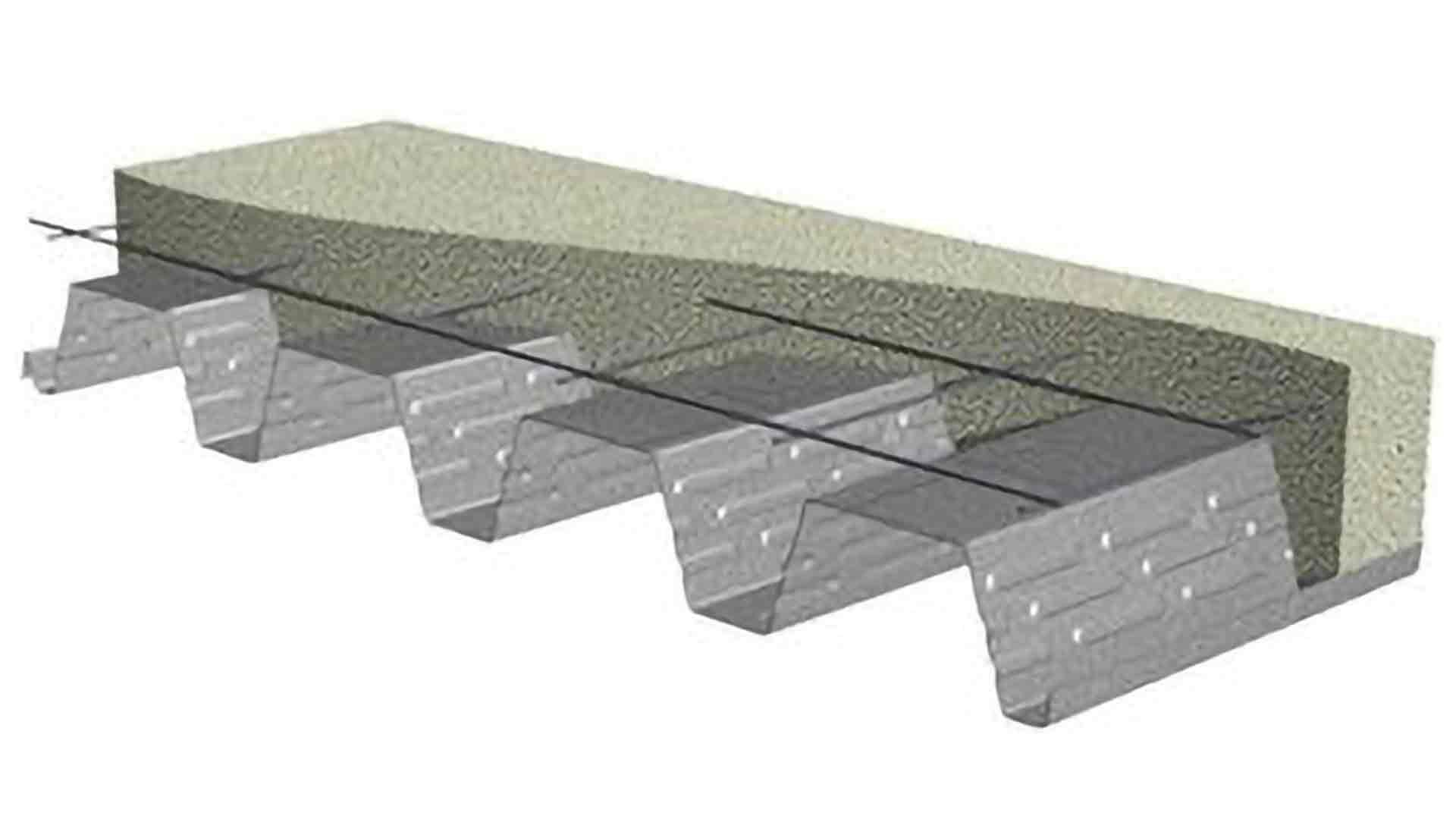

Composite metal floor decking is metal floor deck with an embossment pattern manufactured into the sides (flutes) at regular intervals. The embossments allow the concrete to bond with the metal decking panel as the concrete cures. The main difference between a floor deck and a roof deck is that roof deck does not have the embossments.

Once the concrete curing process is completed the metal decking and concrete become one item bonded together. They become a composite metal floor deck. The strength of this new composite product is greater than the strength of the sum of the two individual parts.

The embossment pattern that is manufactured onto the panel is referred to by different names depending on the decking manufacturer. Verco Decking, for instance, refers to their embossment pattern as FormLok™.

What is FormLok™?

FormLok is the embossment pattern that is manufactured onto Verco metal floor deck panels. The formlok embossment pattern is different on each composite metal deck profile. The FormLok pattern is tested to calculate the strength for different composite deck slabs.

Types of Composite Metal Floor Deck

There are several options when it comes to composite metal floor decking. It is made up of different profiles, which each offer different values in strength. There are 3 different depths of Formlok Composite Metal Decks. Each depth allows for different concrete slab thicknesses. Below are the different types of Formlok Composite Metal Decks.

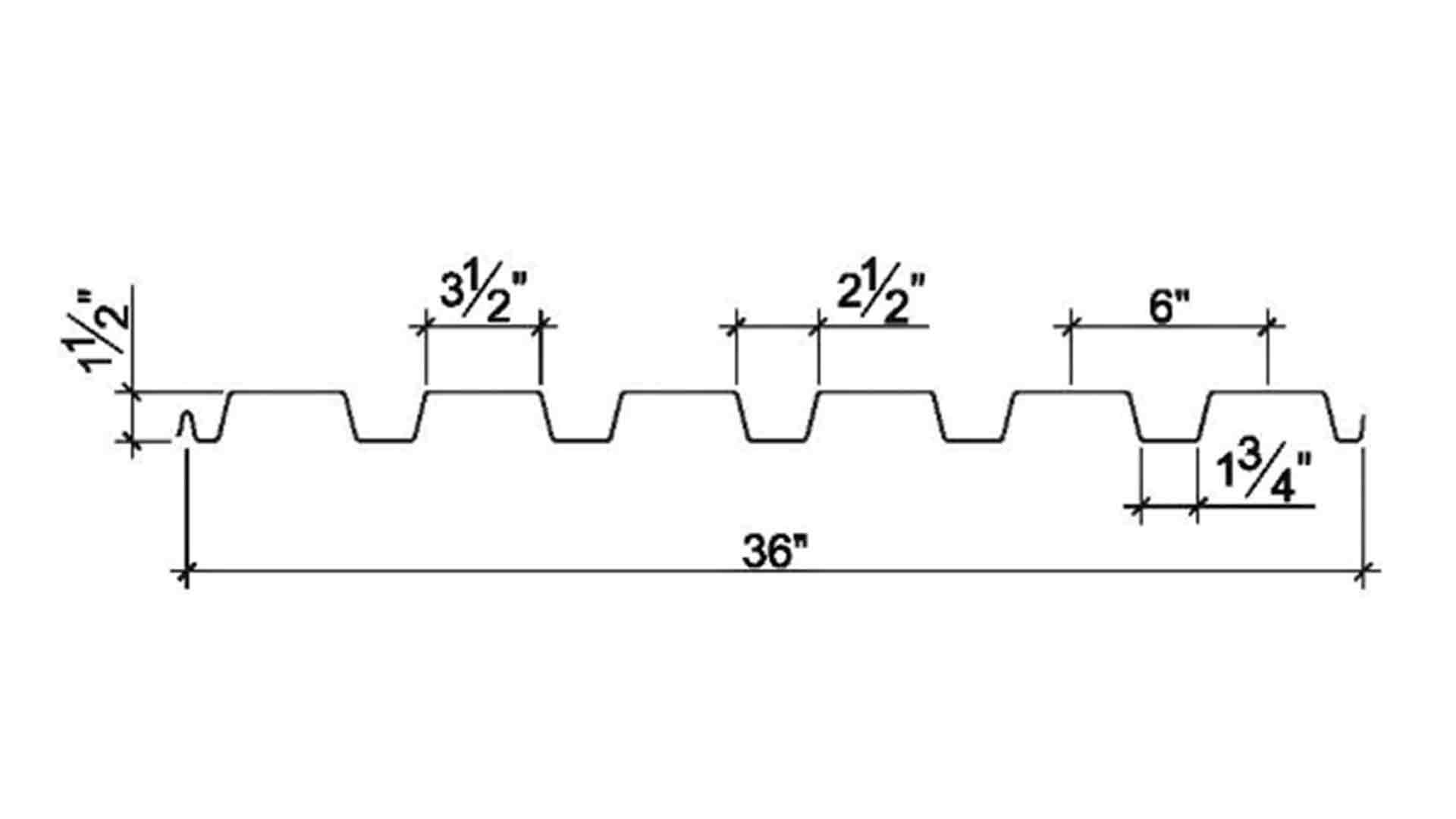

1 ½" Composite Metal Deck Type B-36 Formlok

Type B-36 FormLok is a low profile deck. It is 1.5" Deep, 3' Wide Panel. It allows for normal weight concrete slab thicknesses of between 3.5" to 7.5". This type of panel is used in short span conditions.

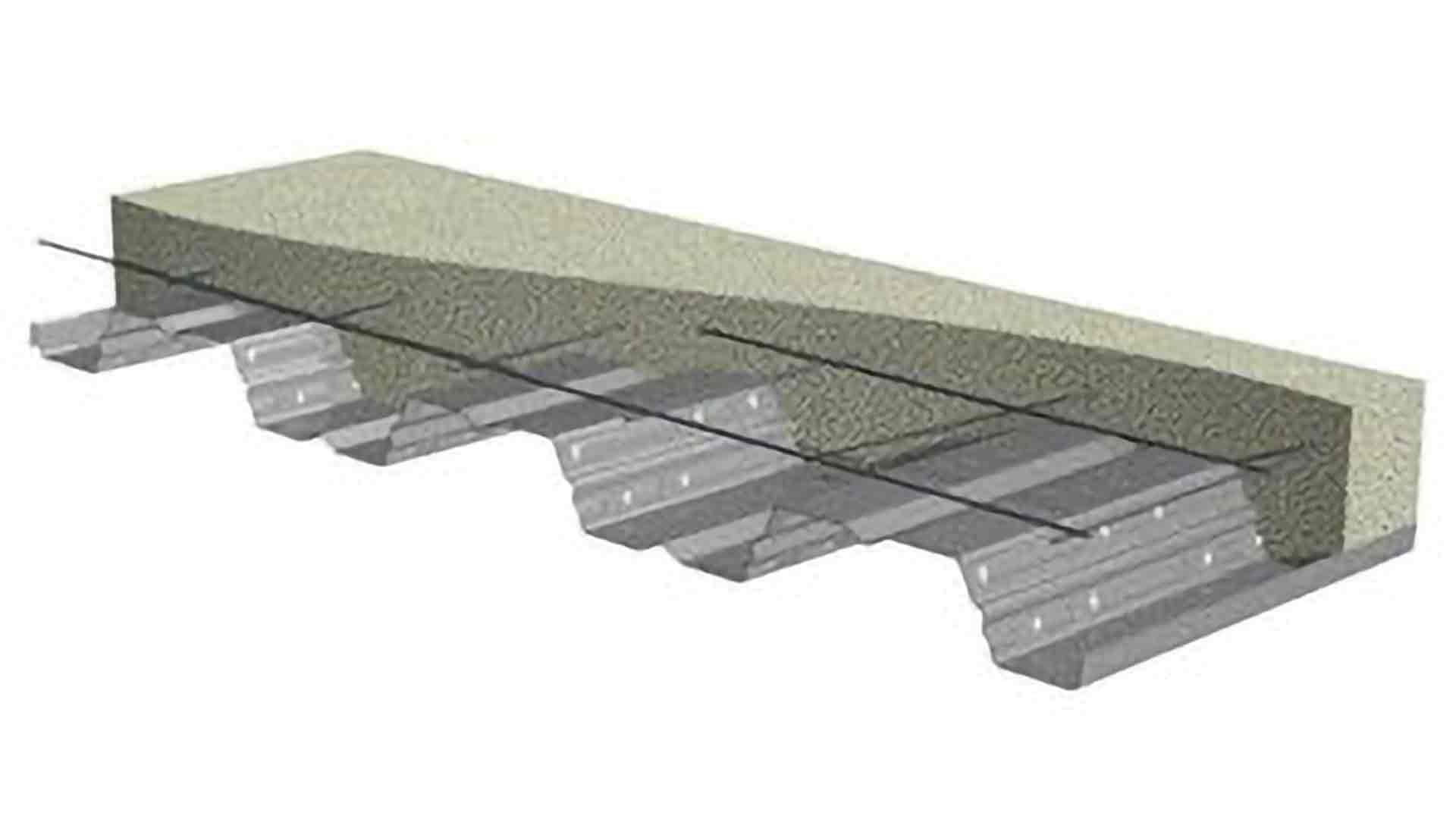

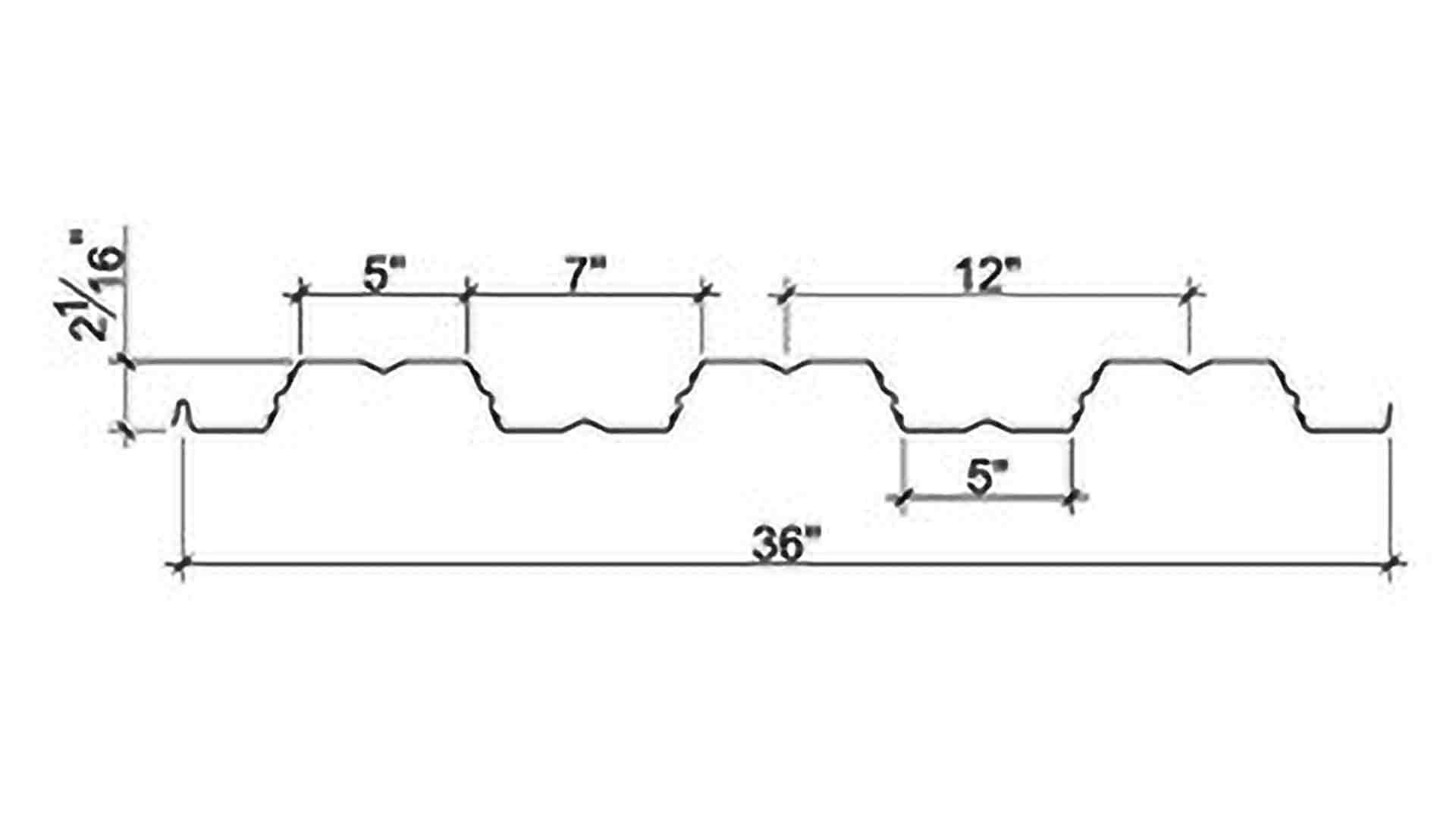

2" Composite Metal Deck Type W2-36 Formlok

Type W2-36 FormLok is a 2" Deep, 3' Wide panel. It allows for a normal weight concrete slab thickness of between 4" to 8". It allows for longer span conditions than the 1.5" deep panels.

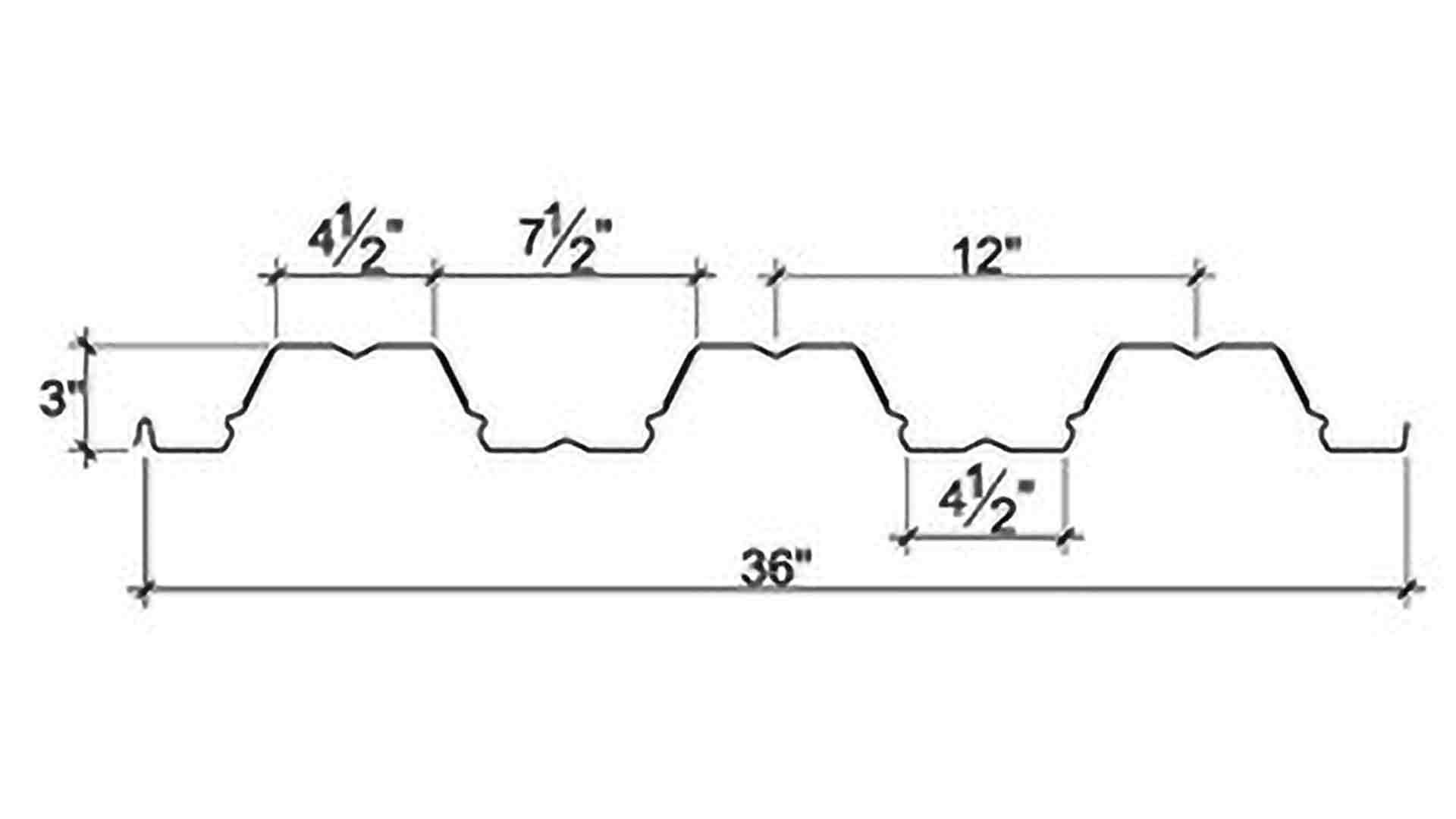

3" Composite Metal Deck Type W3-36 Formlok

Type W3-36 FormLok is 3" Deep, 36" Wide. It is a long span floor deck panel. It can support normal weight concrete slab thicknesses of between 5" to 9".

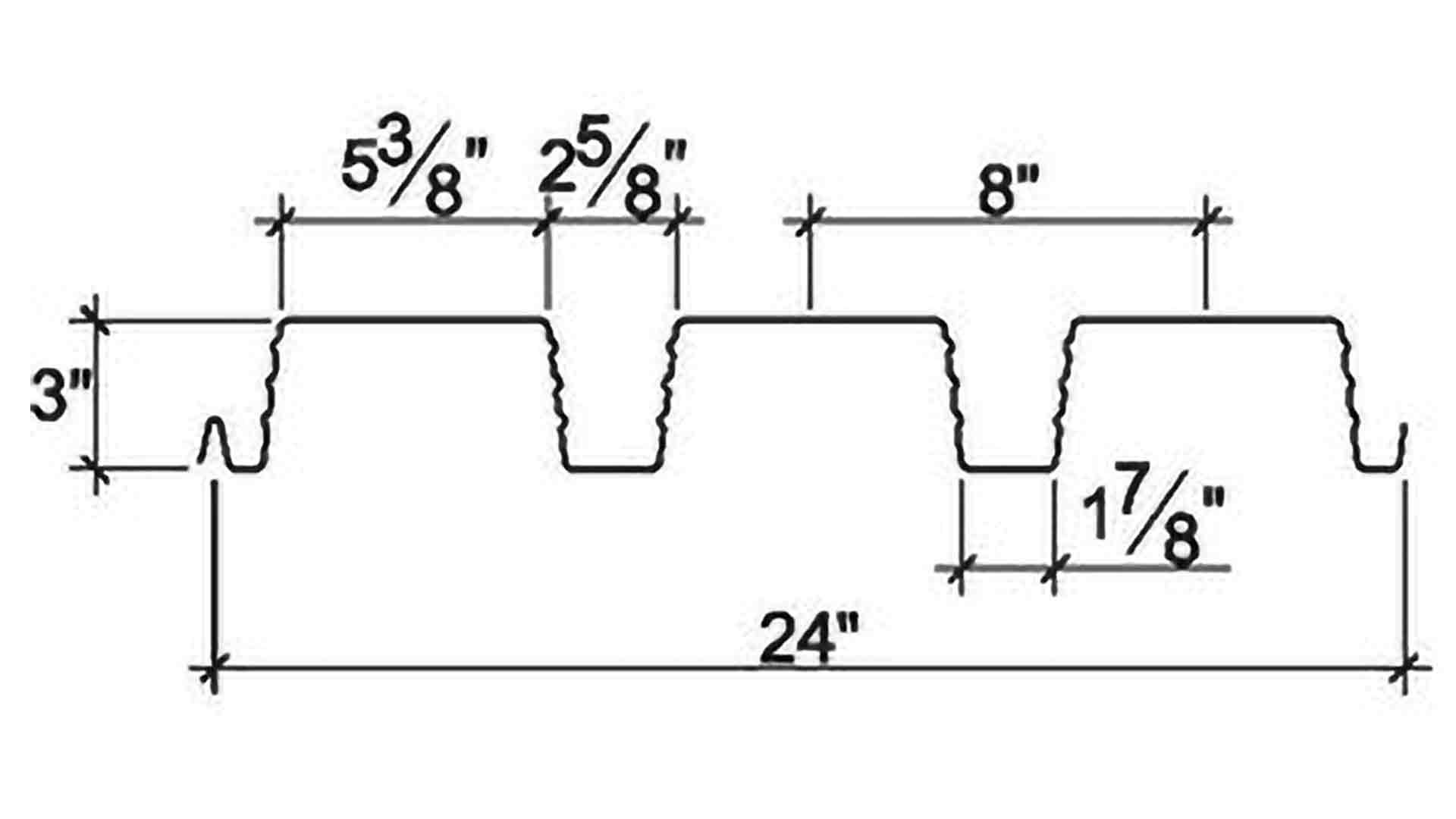

3" Composite Metal Deck Type N-24 Formlok

Type N-24 FormLok is another 3" Deep panel. It is only 24" wide and is used in long span floor conditions. It allows for a normal weight concrete slab thickness of 5" to 9".

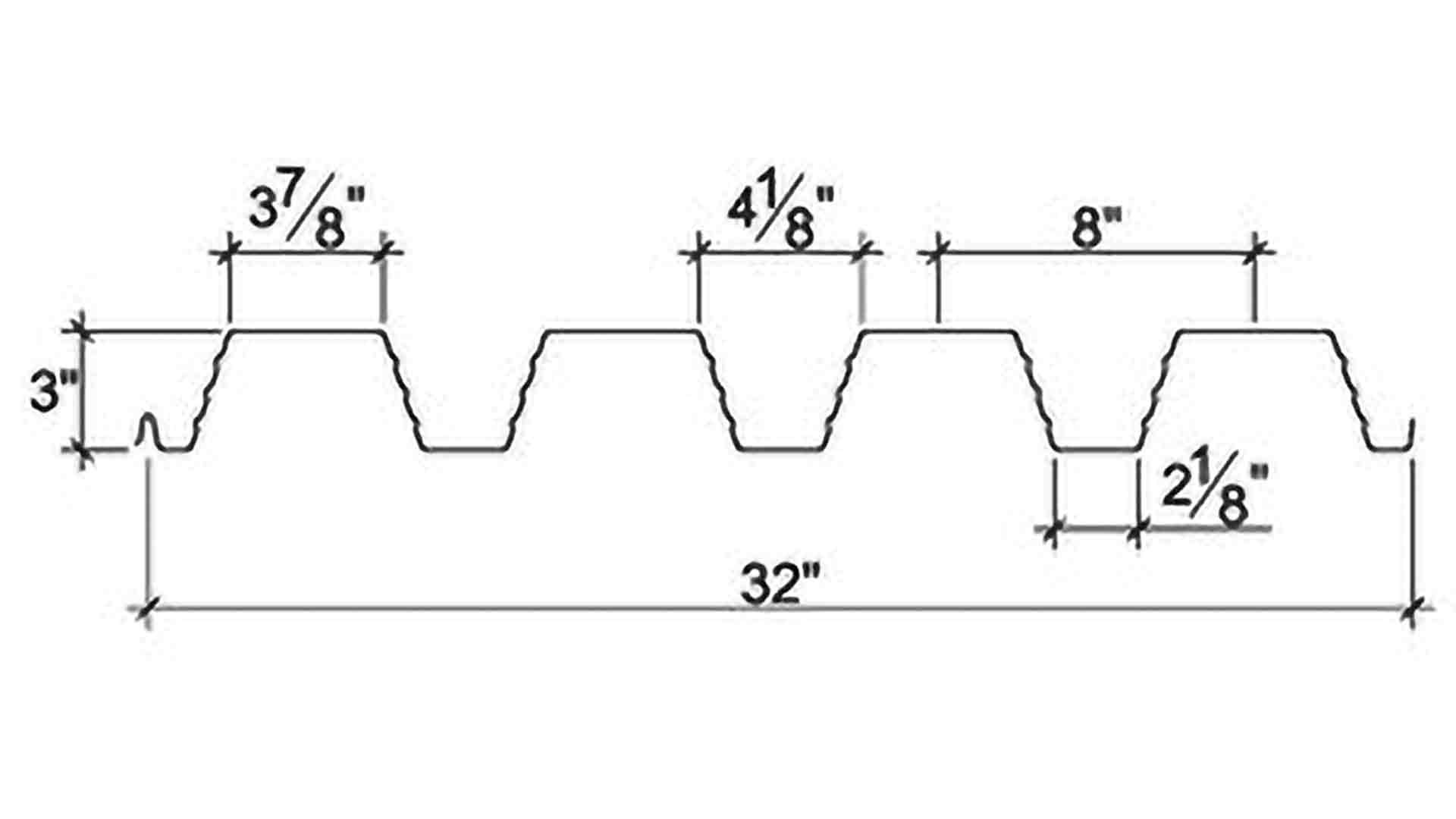

3" Composite Metal Deck Type N3-32 Formlok

Type N3-32 FormLok is another option for a 3" Deep panel. This panel comes 32" wide and is also used in long span floor conditions. It allows for a normal weight concrete slab thickness of 5" to 9".

Composite Metal Floor Deck: Side Lap Types

Composite Metal Floor Deck can be manufactured with 2 different types of side laps. It can be made with the standard interlocking side lap or a screw fastened side lap.

The most common side lap connection type specified on composite metal floor deck is the standard interlocking side lap. It allows the side laps to be connected by Button Punch, PunchLok, or Top Seam Weld. The project plans will specify how the side laps will be connected.

Alternatives to Composite Metal Floor Decking

If you are trying to increase the strength of your floor deck, there are alternatives to using composite metal floor deck or in addition to using composite metal decking.

- Use heavier gauge metal decking

- Locate your secondary steel framing closer together to reduce the metal decking span

- Increase size of your secondary beams

- Put rebar in the slab

- Use deeper metal decking

- Increase the thickness of the concrete pour

One of the main problems with most options is that they add weight to the floor slab, which has a ripple effect. The added weight needs to be supported by the steel framing, connections, columns and footings. The more floors that your building has the bigger problem the additional weight becomes. When you add up all of the affected items, all of the additional weight can end up costing a large amount.

Benefits of Composite Metal Floor Decking

There are a few major benefits of using composite metal floor decking. The first one is the added strength. As mentioned earlier, that strength is produced when FormLok™ embossments allow the concrete to bond with the metal decking panel as the concrete cures.

The second benefit is the FormLok™ embossments do not add any extra weight. The weight of a non-embossed panel and an embossed panel is identical. However, when you add extra weight, you have to account for it in multiple areas. That makes the value of embossed panels much higher when you're looking to strengthen your floor system.

Cost is another benefit of going with FormLok decking. The cost to add the FormLok embossment is only 1¢ per square foot or $1 per 100 square feet. The FormLok embossment manages to add strength to the composite deck slab at a very low cost.

If you have additional questions on the cost of metal decking we suggest this article:

HOW MUCH DOES METAL DECK COST (RATES, FACTORS, & FEES)

If you have a job calling for a composite metal floor deck, we stock 1.5" deep, 2" Deep and 3" deep floor deck in 20 Gauge, 18 Gauge and 16 Gauge in Galvanized G-60 finish. We stock it with the standard interlocking side lap in multiple lengths.

0 Response to "Design Tool For Composite Floor Deck"

Post a Comment